Im Rahmen unserer Kooperation mit der Inside 3D Printing Konferenz sprechen wir heute mit Terry Wohler, Principal Consultant and President der Wohlers Associates, Inc. über das Potential, die Risiken und eine mögliche Zukunft von additiven Fertigungsverfahren. Lesen Sie in diesem Zusammenhang auch unser Interview mit Dr. Eric Klemp.

Probleme und Herausforderungen

Terry Wohlers sieht die größte Herausforderung in der additiven Fertigung beim Übergang von der ursprünglichen Produktion von Prototypen zur Fertigung von Endprodukten. Unternehmen wie Airbus, Boeing, GE Aviation sowie Implantat- und Endprodukt-Hersteller, versuchen die Verfahren zunehmend zur richtigen Produktion der Produkte heranzuziehen. Dieser Schritt birgt einige Herausforderungen wie die Qualitätssicherung und Zertifizierung von Maschinen und Materialien in sich. Dies ist vor allem in der Luft- und Raumfahrt sowie in den medizinischen Bereichen aufgrund der geringen Stückzahlen und einer hoher Komplexität interessant.

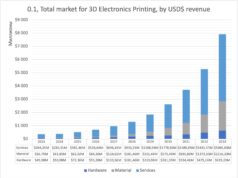

Die zweitgrößte Herausforderungen sieht Wohlers in den derzeitigen Gerät- und Materialpreisen. Die Kosten der Geräte für industrielle Anwendungen befinden sich weiterhin im Bereich von $ 250.000 bis $ 500.000. Während in anderen Bereichen die Materialkosten für die Herstellung von Prototypen weniger ins Gewicht fallen, betragen die Materialkosten bei additiven Fertigungssystemen von Produkten aus der Luft- und Raumfahrt sowie in den medizinischen Bereichen das 50 bis 100-fache von jenen die in herkömmlichen Produktionsverfahren verwendet werden. So betragen beispielsweise die Materialkosten von Produkten aus der Spritzgußform $2-4/kg während das selbe Material für additive Fertigungssysteme $100-300/kg kosten.

Preise, Anwendungen und Tissue Engineering

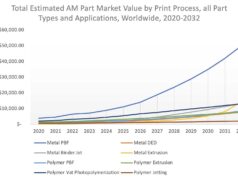

Wohlers erwartet aber mit zunehmenden Wettbewerb ein Sinken der Preise und sieht das höchste Potential für die Luft-und Raumfahrt, für medizinische Anwendungen wie beispielsweise Dentaltechnik sowie bei der Produktion von Schmuck. Für die Produktion von Lego Steinen wird diese Technologie aufgrund der High-Volume Produktion weiter nicht interessant sein. Die Produktion von Ersatzteilen für den menschlichen Körper (“Tissue Engineering”), wie dies vereinfacht in den Medien dargestellt wird, liegt laut Wohlers aber noch in ferner Zukunft. Obwohl die Technologie vielversprechend ist, kann mit derartigen Produkten in den nächsten 5-10 Jahren nicht gerechnet.

Industrielle Revolution?

Wohlers glaubt eher an eine Evolution im Laufe der Zeit als an eine Revolution. Viele herkömmliche Produkte werden weiterhin traditionell gefertigt werden. Das interessante an additiver Fertigung ist seiner Meinung nach, dass professionelle Unternehmen wie Airbus und Boeing derzeit den kompletten Entwicklungs- und Produktionsprozess neu überdenken. Dies wird zu einer Verringerung der Arbeitsplätze aber auch zu Einsparungen an Gewicht und Materialverbrauch führen. Auf breiterer Ebene wird diese Technologie jeden und überall erlauben eigene Produkte zu erzeugen. Aus dieser Perspektive birgt die Technologie in manchen Wegen, Bereichen und Regionen sehr wohl revolutionäres Potential. Aber einen kompletten Wandel der Produktion sieht Wohlers deshalb nicht.

Hewlett Packard´s Engagement in 3D-Druck

HP hat laut Wohlers in den letzten Jahren einiges an Forschung und Entwicklung unternommen. Nach der letzten Ankündigung ist es aber wieder sehr ruhig um das Unternehmen geworden. Der Erfolg von neuen Produkten hängt laut Wohlers davon ab ob das Unternehmen etwas qualitativ und preislich interessantes auf den Markt bringt. Falls dies der Fall ist könnte es einiges an Aufmerksamkeit und Wertbewerb bewirken. Derzeit ist aber noch nichts bekannt.

Ausblick auf 2014

Wohlers erwartet für 2014 eine weitere Welle an Investitionen auch seitens Regierungen, Bildungsinstituten und großen Unternehmen. Was immer die Menschen erwarten wird laut Wohlers auch deren Realität werden. Zumindest wird sich dies im Wert der Aktien abzeichnen. (Lesen Sie in diesem Zusammenhang auch die Prognose der Wohlers Associates.

Das vollständige Interview

Which issues, threats and risks do you see to the advances in 3D printing technologies?

There are many. If you are referring to using the technology for manufacturing parts that go on to final products, that comes with a wide range of challenges and issues. Because if you look at the 25 years’ history of using this technology, it has truly mostly been for prototyping. But the next frontier to apply it to actual manufacturing, and that is what is so interesting, in my view, about this technology and what many companies like Airbus, Boeing, GE Aviation, implant manufactured and consumer products companies etc., they want to use the technology to manufacture. With that comes a lot of challenges associated with qualifying the machines and materials and then certifying the new designs and certifications are really important. It’s required in the case of the aerospace industry and medical parts. They are some other industries which are regulated as well, but these are the two major ones which are adapting this technology for manufacturing, carefully and relatively slowly. But they are two that it works a really good fit, because the volumes are relatively low and the values and complexity are high in terms of the parts that they could manufacture with this technology. So, one challenge is the qualification and certification, another is the fact that most of the machines are designed for prototyping, so they don’t really confirm to qualifications and standards of big corporations. It’s a whole other level.

One of the major obstacles is the cost of the machines and the materials. The machines are quite expensive. Of course we read about these low-cost systems. Those machines are not capable of producing parts that are used for final products, in most cases, certainly not aerospace or medical related parts. These machines are more consumer type of machines. So, the price of machines that major corporations are using for manufacturing and prototyping could cost 250-500K or even more. So, cost is a consideration. Perhaps even a bigger consideration is the cost of the materials. When you are producing low quantities such as prototypes, the cost of the materials is not that big of an issue, because you are only building a few parts and the value of these parts is so high. But when you get into manufacturing quantities that aerospace uses, that could be a problem. Because most of the materials are priced at a 50-100 times more expensively than the similar material produced in traditional manufacturing. If you look around your office, you see a lot of plastic parts, most of them are injection moulded. The material which goes in these parts can cost $2-4/kg. The similar material can cost $100-300/kg for additive manufacturing and so you can see the vast difference.

Where do you see the future in terms of price? With higher demand, will the price go down?

There is no question that there will be increased competition as result of the market growth and as patents expire; there will be a greater number of machines and companies that will be competing. Especially when there is an opportunity to make money even at a much lower cost for machines and materials. Without a doubt, the prices will be driven down through competition and then through volumes too.

In which areas/sectors do you see potential for the future application of additive manufacturing?

Two areas: aerospace and medical industries are really pioneering the use of additive manufacturing. One related to medical, is the dental industry. That has taken off in quite a big way. Many different applications within the dental industry. Another is jewellery. What is interesting about jewellery is that about everybody can become a jewellery designer and manufacturer. Whereas in aerospace and medical that is not the case. There aren’t any regulations for jewellery manufacture, so you and I or anybody can get into the business of designing bracelets, etc. and then manufacturing them. And we have seen that take off in a pretty big way both among professional and amateur jewellers.

Is printing things like liver tissues totally wild or what do you think about this?

There has been quite some research and development in this area and there has been some success in printing cells and the cells grow and survive. I think the media has oversimplified it and written stories that it is already developed and that we can buy replacement body parts soon, like within the next 2 or 3 years, which is not the case. I spoke with the leading person, Anthony Atala, Wake Forest Baptist University Hospital, the top expert on the topic of regenerative medicine and tissue producing through additive manufacturing. I asked him at what time in the future will we see body parts replaced by additive manufacturing? It’s not in the next 5 to10 years. It will be an evolutionary thing. It is already possible to produce it, but it’s very complex.

Could this technology contribute to a new „industrial revolution“?

I don’t know. I don’t think anybody knows. We are seeing some elements of what could be a manufacturing revolution. Honestly, I think it will more be of an evolution. It will evolve over time. We are equipping many people with designing manufacturing tools for the first time. We will continue to manufacture most of our products as we do today: chairs, tables, computers, stadium seats, all these things will continue to be manufactured the way we do now. What is interesting about 3D printing and additive manufacturing, terms that most people use interchangeably now. What is interesting about this, it is creating an entirely new way in design manufacturing. For professionals and for companies like Airbus and Boeing, they are rethinking their whole design and are consolidating assembly lines, several parts into one, etc. This will reduce labor, whole assembly lines will go away, etc. And it will reduce weight and material, which is really important. It’s disrupting the way we think about design. On a broader scale: it really allows anybody located anywhere to become a manufacture. It can be an individual in a small village in Zambia, in some place in Africa where they have access to computers and to internet and that’s pretty much what they need. They could get a small 3D printer, they can start manufacturing. For a new way of development, economic development. From that point, it has the potential to be revolutionary in certain ways, in certain regions, in certain businesses. But as far as it is totally changing everything associated with manufacturing, I don’t see that happening.

Hewlett Packard (HP) announced to come into the 3D printing market in 2014. How could such a market entry look like and what might be the consequences?

HP was in it for a while, they partnered with Stratasys to introduce a HP 3D printer, manufactured and distributed by Stratasys. They had this in place for some time, more than a couple of years. HP has some experience with it. They have also done some research and development over the years. If you look at the patents they applied for and have had granted. They have been very quiet after that announcement. It really depends on if they come out with something in price and quality, it could gain a lot of attention and start this competition. We don’t know anything about it, it’s hard to comment on it.

Will children print their legos at home in 10 years time?

Legos are printed in hundreds and millions. So it’s the wrong extreme. Its very high volume. Aerospace parts have low volume and high complexity. Legos on the other hand are relatively low complexity, very high volume. I think that we will have machines, which will print some customed lego parts that are specialized. The tools are already in place to do that sort of thing. 99% of most legos as they are done today, and 1% will be customed type of legos.

Do you see any major developments in 2014?

We will certainly see the wave of investment continue through 2014 or even accelerate. Because we have seen a lot from the investment community, but now we are going to see more from government agencies at all levels from all over the world and also education institutions, universities and other schools. But most likely from large corporations, they will invest a great deal of money in this. This is something we will began to see and we already begun it to see in 2014.

Perception is reality. Whatever people perceive, it becomes their reality. It becomes reality in the case of the value of the stocks.

Terry Wohlers ist Principal Consultant and President der Wohlers Associates, Inc. und Sprecher bei der Inside 3D Printing Konferenz und Expo am 10. und 11. März 2014 in Berlin.

Terry Wohlers ist Principal Consultant and President der Wohlers Associates, Inc. und Sprecher bei der Inside 3D Printing Konferenz und Expo am 10. und 11. März 2014 in Berlin.