Anfang Juli haben wir über die erfolgreichen Tests von komplett 3D-gedruckten Raketenantrieben von Aerojet Rocketdyne berichtet.

Jetzt erhält die Firma von der Wright-Patterson Air Force Base einen Großauftrag. Mit mehreren großen SLM (Selektives Strahlenschmelzen) Geräten sollen Raketenantriebe für den National Security Spacelaunch erzeugt werden.

Vollständige Pressemeldung:

Aerojet Rocketdyne Awarded Defense Contract for Large Scale Additive Manufacturing

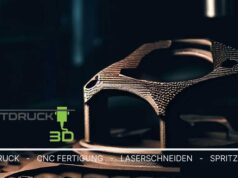

SACRAMENTO, Calif., Aug 18, 2014 – Aerojet Rocketdyne, a GenCorp (NYSE: GY) company, was recently awarded a contract by Wright-Patterson Air Force Base through the Defense Production Act Title III Office for large-scale additive manufacturing development and demonstration. The contract will secure multiple large selective laser melting machines to develop liquid rocket engine applications for national security space launch services. Aerojet Rocketdyne and its subcontractors will design and develop larger scale parts to be converted from conventional manufacturing to additive manufacturing (3D printing).“Our liquid rocket engines have been used for half a century and our products are highly efficient and complex with a safety and reliability record that is unparalleled,” said Jeff Haynes, program manager of Additive Manufacturing at Aerojet Rocketdyne. “Incremental manufacturing advances have been applied over the history of these programs with great success. Additive manufacturing shifts these advances into high gear and ultimately transforms how these engines are produced.”

“We have developed and successfully demonstrated additive-manufactured hardware over the last four years but the machines have been limited in size to 10-inch cubes,” said Steve Bouley, vice president of Space Launch Systems at Aerojet Rocketdyne. “These next generation systems are about six times larger, enabling more options for our rocket engine components. We are extremely honored to have received this contract, and foresee the day when additive-manufactured engines are used to boost and place important payloads into orbit. The end result will be a more efficient, cost-effective engine.”

Under the contract, Aerojet Rocketdyne will demonstrate three different alloys with these larger additive manufacturing machines to include nickel, copper and aluminum alloys. Parts ranging from simple, large ducts to complex heat exchangers are planned to be demonstrated in full scale. The program scope is expected to replace the need for castings, forgings, plating, machining, brazing and welding.