Kai Parthy Entwickler der Laywoo-D3, BendLay, Laybrick Sandstein und PORO-Lay Filaments, präsentiert mit LAY-Ceramic nun ein keramisches Druckmaterial für Fused Filament Fabrication (FFF) 3D-Drucker.

Inspiriert vom Dries Verbruggen (Unfold), entwickelte Kai Parthy von CC-Products in Köln mit LAY-Ceramic ein Keramikpulver / Polymer Mischmaterial zum Drucken von keramischen Objekten. Die derart gedruckten Objekte werden in einem Ofen nachgebrannt. Das Material ist noch experimentell aber äußerst interessant. Die Schrumpfung beträgt zwischen 20-30 %.

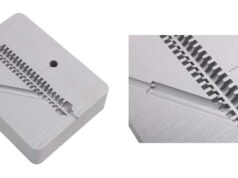

Zum Verarbeiten sind einige Modifikationen am 3D-Drucker notwendig. So wird neben einem “full metal hotend” von PRUSA oder E3D eine Filamentschraube aus gehärteten Stahl (“hobbed bold”), sowie ein Filament “warmer” notwendig. Auch ein Ofen zum Nachbrennen ist erforderlich.

LAY-CERAMIC

A new experimental filament out of Kai Parthy ́s box.

With the Lay-Ceramic filament you can create objects that can be fired to hard pottery.Why did you developed this “filled” filament ?

I was inspired by entusiasts like Dries Verbruggen (Unfold) working with his porcelain paste extruders

since some years.

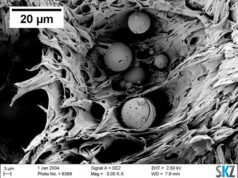

A little optimistic, I tried to fill ceramic powder (started more than two years ago) into my polymer blends to see what would be happen in a procedure of

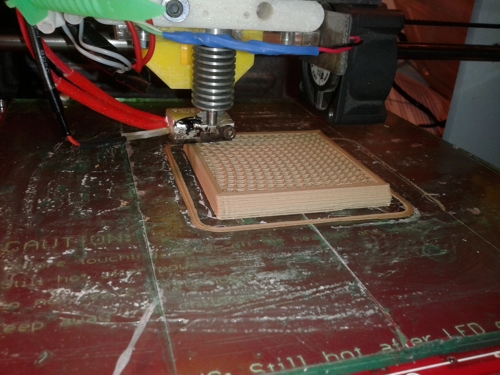

- printing with my home reprap

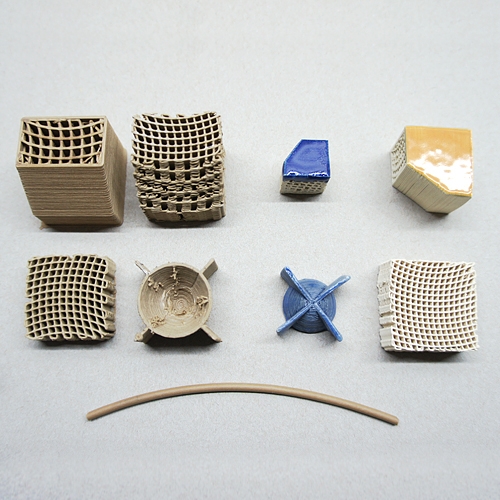

- debindering the polymer component in a temperature controlled oven / kiln

- sintering the remaining mineral object to a hard ceramic by heating up to 1200°C

- glazing the object with enamels to make it waterproof or decorative

Is special equipment needed?

Yes, but only some modifications for the printer

For the printer:

- a full metal hotend from PRUSA or E3D is required, with short and effective warming zones and good cooling fins, both are neccessary for my “ filled” wires !

- a hobbed bolt made from hardened steel , ebay! with best grip, because the molten filament is very viscous and is resistant against to be pushed into the hotend

- and a filament warmer, a flexible tube to heat the filament up to 35-40 degrees before pushed into the hotend, this will make the filament less brittle.

For the thermal treatment:

- a kiln ( ceramic burning oven ) cheap on ebay

- a temperature controller (under 80 Euro) for stepwise debindering in a range from 250° to 500°C and a sintering period up to max. 1200°C

Whats going on?

Today I would say the filament is in an experimental status.

I do only test small objects since my oven has only a small opening. Furthermore the debindering process has to be optimized for thick wall objects (today I found good values for 1-2 perimeter objects). I also reach a total shrinkage rate of 20 -25 percent after the last sintering step. Ofcourse I would like to reduce this value. Also, I plan to fill the basic polymer instead of clay or porcelain with metall-powder for printing and sintering steel objects 😉 On otherhand the filament needs some fine tuning.

But, like my development of POROLAY, I have experienced long delays and missing production capacities for special filaments.

My next step is to increase my cooperation with my friends from REPRAPUNIVERSE (Achatz- Industries).

Father Franz and son Richard Achatz produce Reprap 3D printers in the Netherlands (close to Aachen, Germany) so it is easy for my to reach both.

They will adapt the required hardware for printing ceramic into theire standard printer Prusa i3.

We believe that potters who wanna start in 3D printing will be happy to get a printer that is already tuned for ceramic, can also print standard thermoplastics as PLA and ABS or Nylon.

(c) Pictures & Link: Kai Parthy, CC-Products / Köln